Wheat beers such as hefeweizen, weissbier and wit are all light beers made from a mix of malted barley and wheat. In southern Germany the typical hefeweizen is fermented with a non-flocculating yeast, and it is not filtered before bottling. This gives the beer a yeasty, bread like flavor accompanied by aromas reminiscent of banan, cloves (we’ve encountered that combo before), coriander and citrus. I’ve just begun to read up on brewing and my first batch of a partial mash hefeweizen is bubling along. As I pitched the liquid hefeweizen yeast into the wort I decided to keep a tiny amount for baking. If hefeweizen beer is reminiscent of bread, why not use the yeast for making bread? In particular I was curious whether some of the aroma top notes characterizing hefeweizen beer would stand out in bread made using the same yeast.

The specific yeast I used was obtained as a liquid suspension from White labs. Their hefeweizen yeast strain (catalogue number WLP300) is identical to Weihenstephan 68. And in case you didn’t know – Weihenstephan is the world’s oldest brewery. Wine yeast is the same as beer yeast (or ale yeast to be more precise) and baker’s yeast – and they are all known under the latin name Saccharomyces cerevisiae (which literally translates to something like a “beer producing sugar munching fungi”). Why bother if they are all the same yeast you may ask. It’s a good question, but despite the common name they are different isolates with very different properties. They certainly have a lot in common: in the presence of air they consume sugars to grow, and in a closed environment without access to air the consumed sugars are instead converted to alcohol and carbon dioxide. But besides this main reaction there are hosts of other enzymes present that produce higher alcohols, aldehyes, acids, esters – all of them volatiles compounds that contribute significantly to flavor. And this is typically where the isolates of S. cerevisia differ. There’s a mind boggling array of beer yeasts available. Take a look at the yeast catalogues of White labs, Wyeast or Fermentis to get an idea of the many yeast strains that are available (note that the lists includes both ale yeasts S. cerevisia which are top fermenting and lager yeasts S. carlsbergensis which are bottom fermenting, meaning that the yeast sinks to the bottom when the job is done). And if this doesn’t impress you – consider the fact that there are thousands of S. cerevisia isolates available from culture collections around the world (ATCC and CBS are among the largest – do a search for S. cerevisiae at ATCC and it tells you to narrow your search because there are more than 5000 hits!).

Apart from the specific strain used the fermentation conditions will also greatly influence the volatile profile: temperature, time, pH, micro and macro nutrients present, and the sugars available all have their say. A general advice for artisan breads is to use only a small amount of yeast (2-3 g) to start with and give the dough plenty of time to develop and rise. This gives a richer flavor compared to using 50 g of fresh yeast to obtain a rapid rise. Since I only started with about a 1/4 teaspoon of yeast slurry I first had to let the yeast grow and multiply. Since S. cerevisiae needs oxygen to grow I added 50 g of water to the yeast slurry and then used a hand mixer to whip in air for a minute or so before adding 50 g of flour. I left the pre-ferment (aka poolish or biga) on the benchtop and the next day there was plenty of bubbling activity. I added more water, whipped in more air with a hand mixer and once again added as much flour as water. This yielded an active starter and all was set for baking.

Hefeweizen bread

Pre-ferment (evening before baking day):

65 g starter (100% hydration)

110 g water

110 g all purpose wheat flour

Baking day:

285 g starter (100%) from day before

466 g water

250 g emmer

485 g all purpose wheat flour

12 g salt

Total dough weight: 1498 g

Hydration: 69%

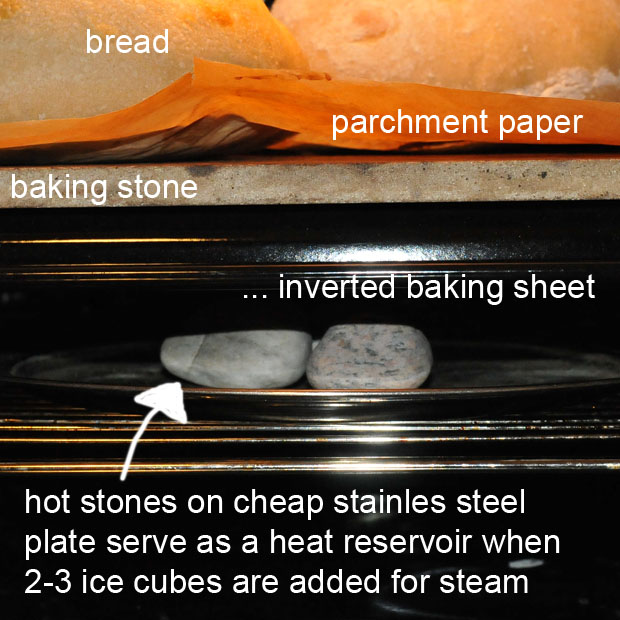

Add water to starter and incorporate air with a hand mixer to give the yeast a good start. Mix in the flour, cover and leave at room temperature. Next day, mix all ingredients and leave to rise (this may take 1-3 hours). Divide in two, fold over repeatedly and shape into boules. Leave to rise. Preheat oven to 250 °C. Use a baking stone, and generate some steam in the oven during the first 10 min (see picture below). After 10 min, turn down to 220 °C and bake until crust has a nice golden crust.

My current steam setup: I use ice cubes since this prevents a sudden gush of steam towards my hands. The stones serve as a heat reservoir ensuring that the ice cubes melt and evaporate within a couple of minutes. To cope with the heat shock I use a plate of stainless steel to hold the stones. After 10 min I open the oven door to vent out steam and remove the plate with the stones to allow an even heating (no reflection!) of the baking stone from below.

So how did it taste? The bread tasted excellent, but to be honest – I couldn’t detect any aroma that I can’t get using conventional baker’s yeast. The reason for this is probably that other flavors (i.e. from the flour, the baking process etc.) dominate. Another factor is that bread is only fermented for a couple of hours compared to several days for beer. This simply doesn’t give enough time for significant concentrations of the volatile compounds to develop. Lastly, the baking process will drive off the most volatile compounds. Nevertheless, I would still encourage you to try this! I didn’t get the result I hoped for (I was a little optimistic), but it’s a fun experiment to do, especially if you have some yeast left over from beer brewing anyway.

I am by no means the first to try this. But it seems that results are mixed. Some complain about slow rising doughs. But there are also many misconceptions around. One is that some yeasts produce more alcohol whereas other yeasts produce more gas. As long as we’re talking about anaerobic fermentation of sugar to ethanol and carbon dioxide this is plain wrong as ethanol and carbon dioxide are produced in a 1:1 ratio. There is also some confusion with regards to the naming (i.e. beer yeast, ale yeast, brewer’s yeast, baker’s yeast etc. – when all in fact are the same yeast).

Since the bread came out just like bread made with conventional baker’s yeast it’s fair to turn the question around: Do the different beer yeasts really make a difference? I did a quick search in the scientific littereature and found a couple of papers that study the effect of yeast strains on the formation of volatile compounds in beer and wine:

Yeast Influence on Volatile Composition of Wines

Ester Concentration Differences in Wine Fermented by Various Species and Strains of Yeasts

Synthesis of volatile phenols by Saccharomyces cerevisiae in wines

Function of yeast species and strains in wine flavour

Expression Levels of the Yeast Alcohol Acetyltransferase Genes ATF1, Lg-ATF1, and ATF2 Control the Formation of a Broad Range of Volatile Esters

I haven’t had the opportunity to dig really into this, but from the abstracts it definitely seems to be the case that the selection of yeast strains also play a vital role in the resulting aroma profile of the beer.

Oh yeah, one more thing: For this particular bread I used emmer from a local mill, Holli Mølle, specializing in ancient cereals. Emmer (aka farro) doesn’t form as much gluten as conventional wheat (I tried making a 100% emmer no-knead bread which tasted nice but was a fiasco shape wise…), but it does lend a light greyish/brown color to the crumb and also gives the bread a richer flavor. But the use of emmer is of course not a pre-requisite if you want to bake with beer yeast

Looks good and tastes good!